BACnet is a registered trademark of ASHRAE. ASHRAE does not endorse, approve or test products for compliance with ASHRAE standards. Compliance of listed products to the requirements of ASHRAE Standard 135 is the responsibility of BACnet International. The BTL logo is a registered trademark of BACnet International.

BACnet and Modbus are available only on series HTN104.

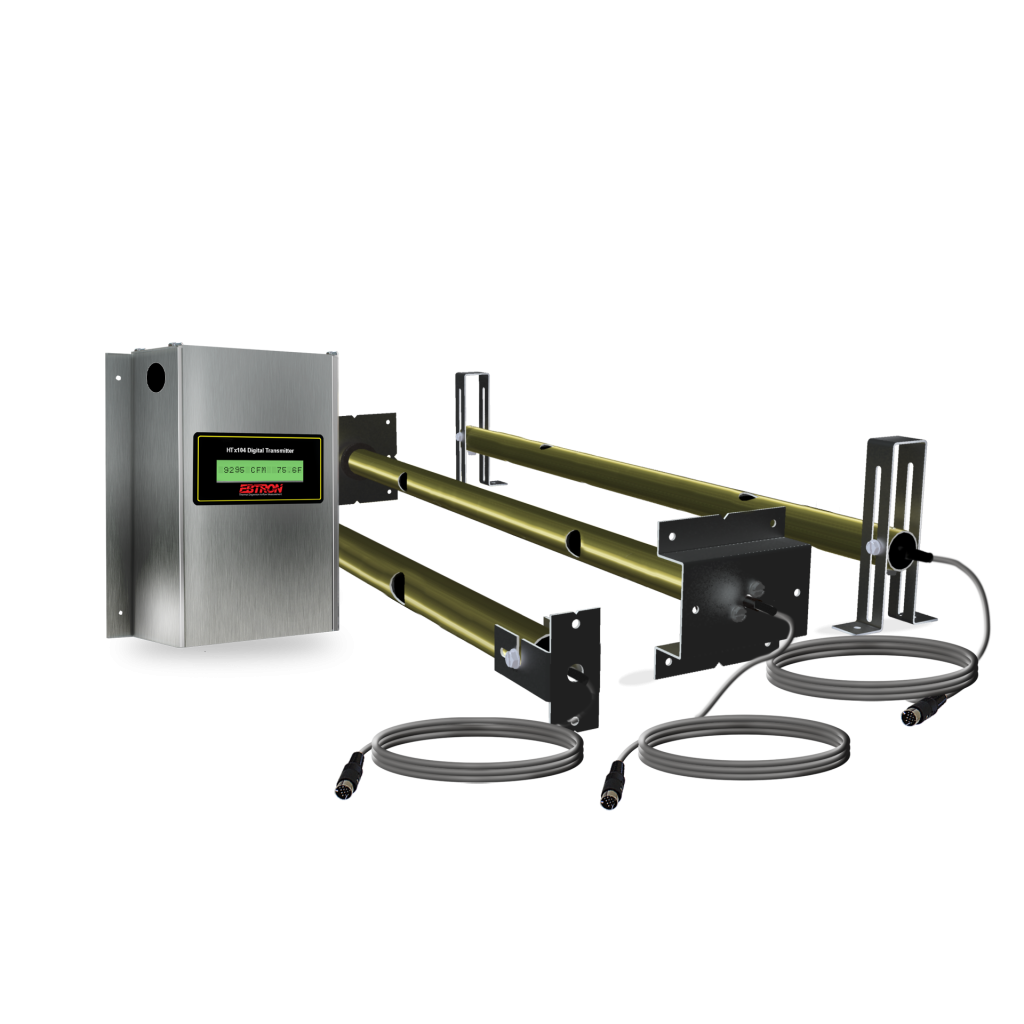

The HTx104-PE is EBTRON’s most economical solution for larger systems when “out-of-the-box” installed accuracy is not required and field adjustment is acceptable. Perfect for LEED outdoor air delivery monitoring or other low sensor density airflow measurement applications.

Probe and Sensor Node Configurations (max.)

1 probe x 4 sensor nodes/probe

2 probes x 2 sensor nodes/probe

Installed Airflow Accuracy¹

≤ 2 sq.ft. [0.185 sq.m.]: [0.18 sq.m]: ±3% of reading

> 2 sq.ft. [0.185 sq.m.]: ±(3% to 10%), typical (increases with increasing duct size). May be improved by field adjustment using the Field Adjust Wizard (FAW) to a reliable reference.

Sensor Density

Refer to the PC sensor density table.

Sensor Node Averaging Method

Airflow: Independent, arithmetic average

Temperature: Independent, velocity weighted average

Listings and Compliance

UL: UL 873 Listed CSA C22.2 No. 24

CE: European shipments only

UKCA: UK shipments only

BACnet International: BTL Listed (HTN104 transmitter)

FCC: This device complies with Part 15 of the FCC rules

RoHS: This device is RoHS2 compliant

Environmental Limits

Temperature:

Probes: -20 to 160 ⁰F [-28.9 to 71.1 ⁰C]Transmitter: -20 to 120 ⁰F [-28.9 to 48.9 C]

Humidity: (non-condensing)

Probes: 0 to 100%

Transmitter: 5 to 95%

Sensing Node Sensors

Self-heated sensor: Precision, hermetically sealed, bead-in-glass thermistor probe

Temperature sensor: Precision, hermetically sealed, bead-in-glass thermistor probe

Sensing Node Housing

Material: Glass-filled Polypropylene (Kynar® with /SS option)

Sensor Potting Materials: Waterproof marine epoxy

Sensing Node Internal Wiring

Type: Kynar® coated copper

Airflow Measurement

Accuracy: ±2% of reading to NIST-traceable airflow standards (includes transmitter uncertainty)

Calibrated Range: 0 to 5,000 fpm [0 to 25.4 m/s]Calibration Points: 16

Temperature Measurement

Accuracy: ±0.15 ⁰F [0.08 ⁰C] to NIST-traceable temperature standards (includes transmitter uncertainty)

Calibrated Range: -20 to 160 ⁰F [-28.9 to 71.1 ⁰C]Calibration Points: 3

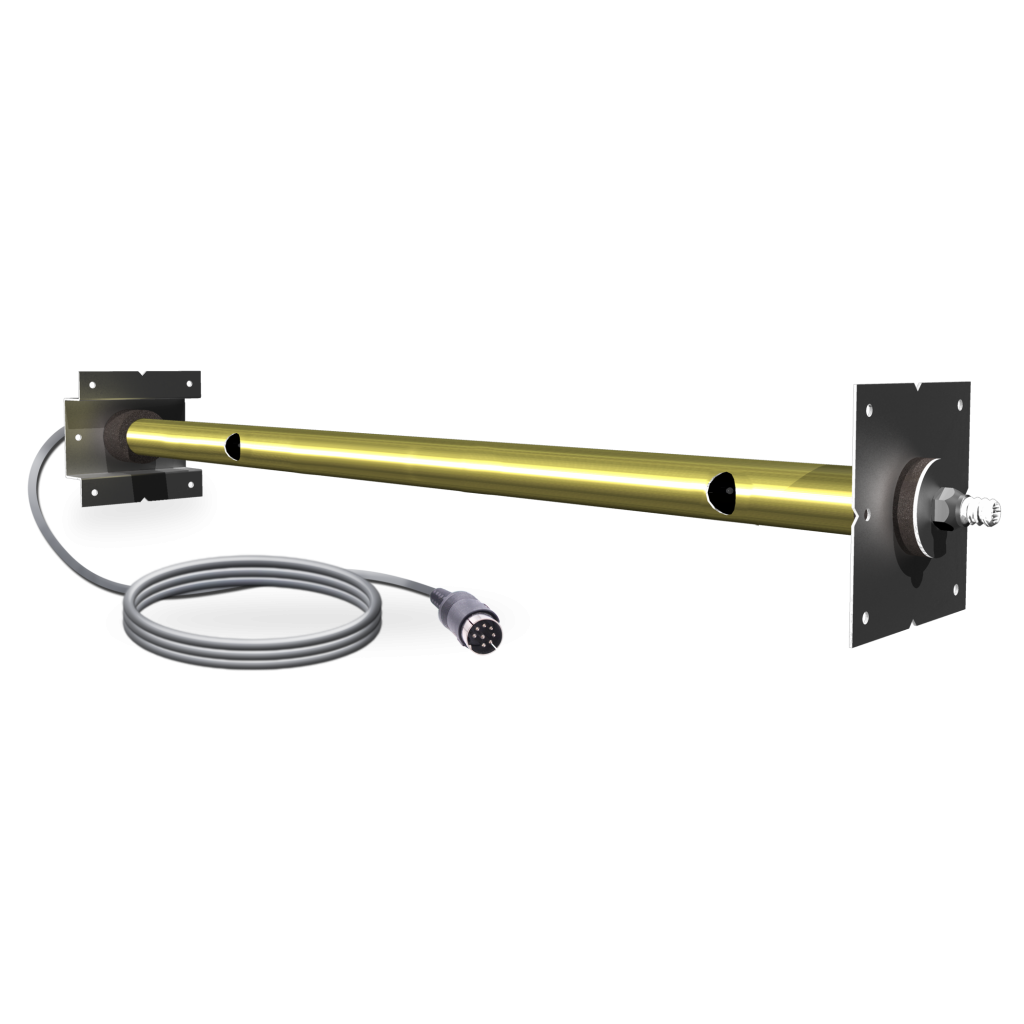

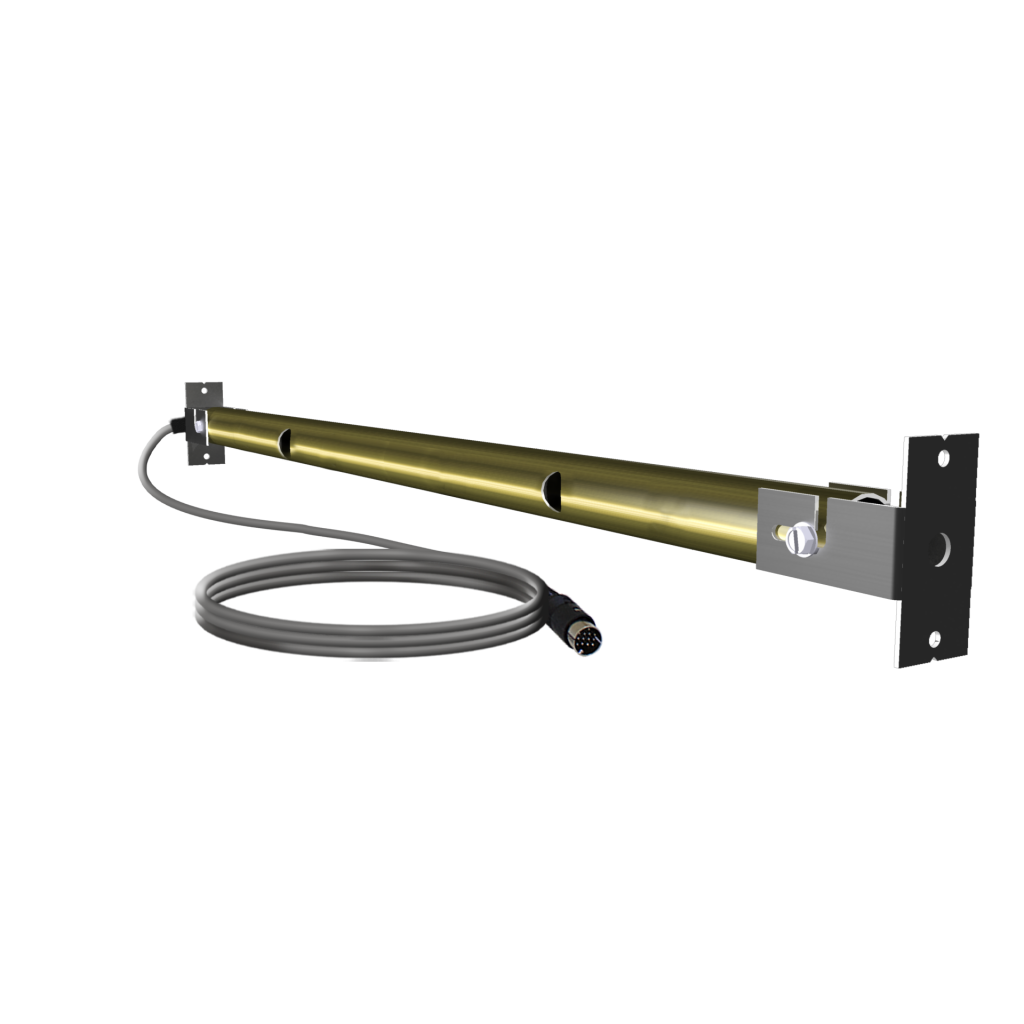

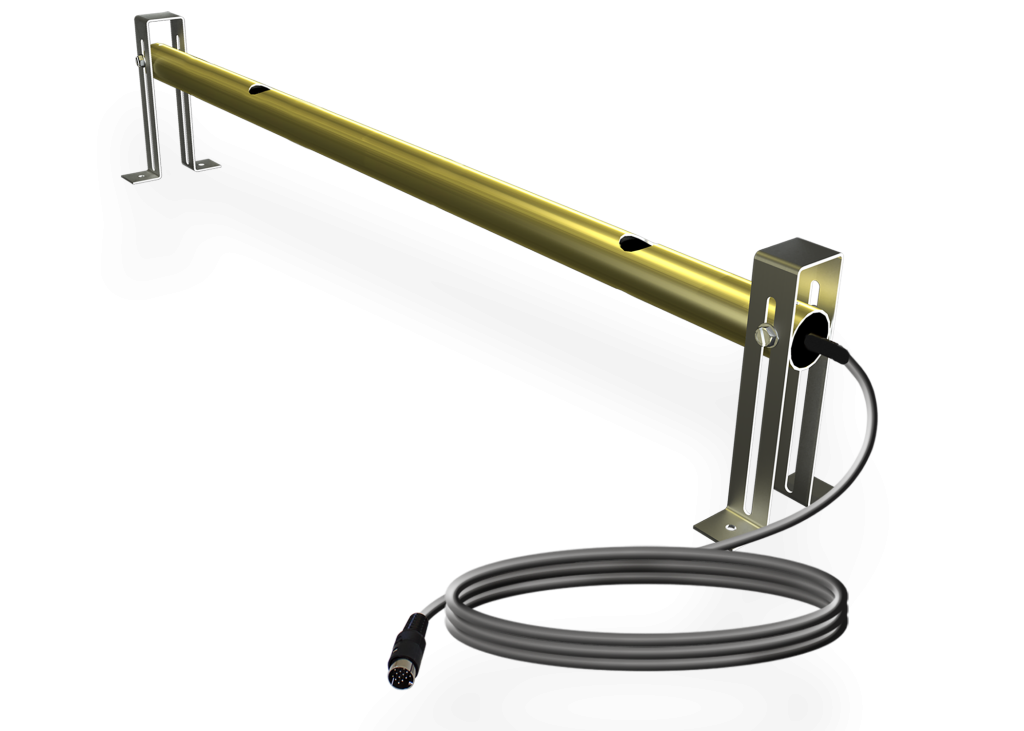

Tube

Material: Gold anodized 6063 aluminum (316 stainless steel with /SS option)

Mounting Brackets

Material: 304 stainless steel

Options & Standard Size Limits2

Insertion: 6 to 191 in. [152.4 to 4851 mm]Stand-off: 6 to 190 in. [152.4 to 4826 mm]Internal: 8 to 194 in. [203.2 to 4928 mm]

Probe to Transmitter Cables

Type: FEP jacket, plenum rated CMP/CL2P, UL/cUL listed, -67 to 302 ⁰F [-55 to 150 ⁰C], UV tolerant

Standard Lengths: 10, 15, 20, 25, 30, 40 and 50 ft. [3.1, 4.6, 6.1, 7.6, 9.1, 12.2 and 15.2 m]Connecting Plug: 0.60” [15.24 mm] circular DIN

Power Requirement:

24 VAC (22.8 to 26.4 under load) @11V-A

PCB Connections:

Gold-plated PCB interconnects and test points

User Interface:

16-character LCD display and 4 button interface

B.A.S. Connectivity Options

HTA104 Transmitter: Two field selectable (0-5/0-10 VDC or 4-20mA), scalable and isolated analog output signals (AO1=airflow, AO2=temperature or alarm)

HTN104 Transmitter: One field selectable (BACnet MS/TP or Modbus RTU) and isolated RS-485 network connection- Individual sensor node airflow rates and temperatures are available via the network

Airflow Alarm

Type: Low and/or high user defined setpoint alarm

Tolerance: User defined % of setpoint

Delay: User defined

Zero Disable: Alarm can be disabled when the airflow rate falls below the low limit cutoff value (unoccupied periods)

Reset Method: Manual or automatic

Visual Indication: Yes, LCD display

Network Indication: Yes (HTN104 only)

Analog Signal Indication: Yes, on AO2 assignment (HTA104 only)

System Status Alarm

Type: Sensor diagnostic system trouble indication

Visual Indication: Yes, LCD display

Network Indication: Yes (HTN104 only)

Analog Signal Indication: Yes, on AO2 assignment (HTA104 only)

¹Installed airflow accuracy allows for additional uncertainty that results from averaging a finite number of sensors in a contorted velocity profile created from up and downstream disturbances. The specified installed accuracy is based on the PE sensor density rules for installations that meet or exceed EBTRON minimum placement requirements. PE sensor density rules may not be available for all duct sizes due to sensor placement limitations (see PE sensor density tables for more information).

© 2023, EBTRON, Inc.