The Importance of Airflow Measurement

ABSTRACT

Outdoor air is essential to dilute airborne contaminants. The COVID-19 pandemic demonstrated that inadequate outdoor air ventilation increased transmission between occupants. Under-ventilation of outdoor air also affects building pressure, increasing moisture levels in the building envelope and ventilation zone. Excessive moisture is a prerequisite to mold and fungal growth and contributes to poor IAQ and thermal comfort. Mechanical codes, including the IMC and UMC, and energy codes, including the IgCC and California’s Title 24, specify outdoor air ventilation rates for compliance. However, most buildings are deficient in code-required ventilation during operation.

In many cases, ventilation rates are compromised because of building operational changes and/or a lack of proper HVAC maintenance. Under-ventilation is a result of improper or inadequate system control. Providing too much outdoor air also has its consequences. Outdoor air conditioning is a significant portion of a building’s energy footprint, and over-ventilation will significantly increase energy consumption. The widespread use of carbon dioxide (CO2) as an indicator of IAQ has contributed to increased ventilation problems. CO2 is often wrongly regarded as a direct measure of air quality, with lower levels indicative of a “safe” indoor air environment. CO2 is simply a proxy to estimate the outdoor air ventilation rate per person entering a ventilation zone. Lag from the CO2 production of occupants entering a previously unoccupied space can result in low CO2 levels during periods of under-ventilation, and assumptions regarding the CO2 production rates of the occupants, combined with measurement uncertainties, result in wide fluctuations in the outdoor air ventilation rate for a given CO2 level. CO2 ventilation control (Demand Control Ventilation, CO2-DCV, or simply DCV) is heavily promoted and often required as an energy-saving strategy. The method gets support from energy managers, government organizations, and building owners, regardless of its potential adverse effect on ventilation.

There are no “IAQ Police” after code enforcement certifies a building for occupancy. During operation and after the building is handed over to the owner, the code requires outdoor airflow rates to be monitored and documented. This minimizes the engineer’s and owner’s IAQ liability and optimizes energy consumption. Monitoring outdoor airflow rates for control can compensate for ventilation variability that results from fan speed variations, damper issues, and filter loading. External factors, including wind and stack pressure effects, exacerbate the problem. This applies to recirculating air handling and DOAS (dedicated outdoor air) systems. These factors can cause outdoor air ventilation rates to vary more than 50% of the desired setpoint.

Monitoring for control is essential when CO2-DCV is employed to maintain upper and lower airflow limits and avoid significant over- and under-ventilation of outdoor airflow rates. An improved technique uses the CO2 level and the measured outdoor airflow rate to estimate the population of the ventilation zone and provide the actual code required ventilation in accordance with ASHRAE Standard 62.1-2022. ASHRAE Standard 62.1-2022 requires outdoor air ventilation for the actual number of occupants when a DCV strategy is employed. In many cases, CO2 should be used only as a high-limit indicator of inadequate ventilation. The outdoor airflow rate should be set based on the measured occupancy of the ventilation zone from occupancy counting sensors, point-of-sale systems, electronic ticket counters, or other occupancy counting techniques.

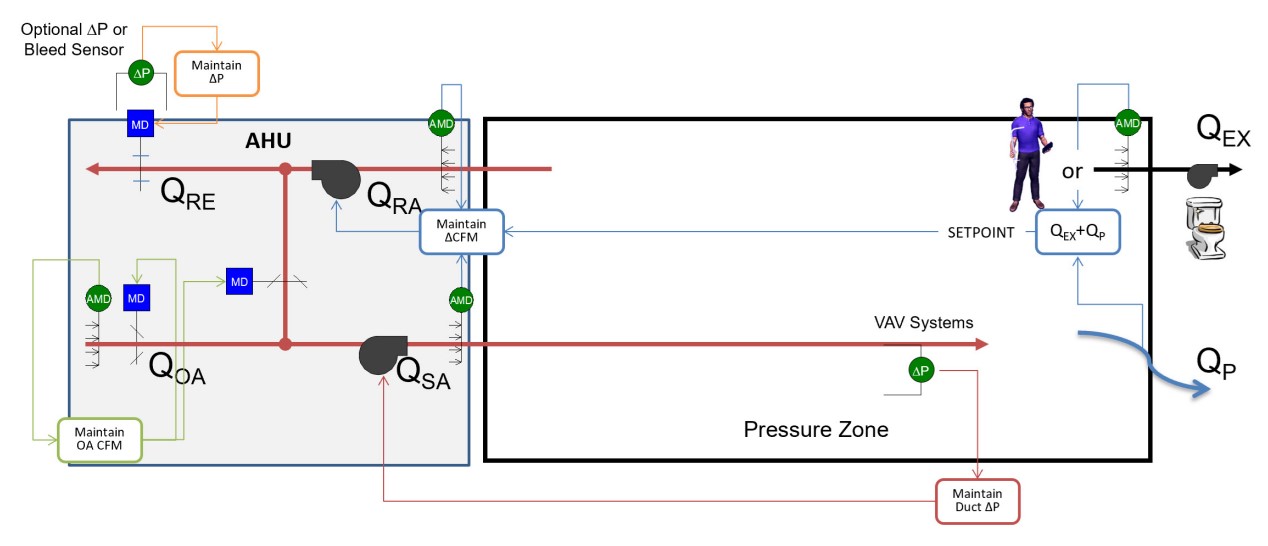

Thermal dispersion airflow measurement devices should directly measure outdoor airflow rates. Differential pressure-based devices, vortex shedders, and other technologies cannot accurately determine the low airflow rates of most outdoor air intakes. Calculated methods that rely on outdoor, return air, and mixed air temperatures or the difference between the supply and return airflow rates have uncertainties more significant than 20% and should always be avoided. Methods that rely on damper position, pressure drop across a louver or damper, or any method that requires field measurement and setup should be avoided on most systems because of field measurement uncertainty. Monitoring the supply and return of outdoor air and exhaust airflow rates to control the pressurization flow is essential to maintain compartmentalized “building pressure” during occupied and non-occupied periods. Positive building pressure limits the migration of untreated outdoor air into a building. This is extremely important in humid climates during high dewpoint periods when moisture transport during negative building pressure operation contributes to mold and fungal growth.

EBTRON’s thermal dispersion technology is built around a high-performance bead-in-glass thermistor probe that is oven aged for nearly four weeks to ensure long-term, drift-free performance prior to individual calibration in controlled temperature circulating baths. Thermistors are potted in a saltwater and acid-resistant assembly backed by independent laboratory testing. Each sensor node is tested at multiple airflow rates in tunnels calibrated to NIST traceable airflow standards. Various models are available for duct, plenum, and fan inlet measurements. Models are comprised of one to sixteen sensor nodes. A microprocessor-based transmitter independently processes each sensor node to provide a true average airflow output. Each sensor node also calculates ambient temperature to provide an accurate, velocity-weighted temperature of the airstream. An optional humidity sensor provides dewpoint, velocity-weighted humidity, and/or velocity-weighted enthalpy. Isolated, linear, analog output signals are standard. Network connectivity: BACnet, Modbus (RS-485 and Ethernet), and LON are available. With the USB datalogger configuration and the EB-Link App installed, data trends can be achieved without a network connection.

Uncontrolled airflow rates affect occupant health, well-being, and thermal comfort. When you combine occupant benefits with the decrease in engineer and owner risk, the cost of airflow measurement (typically $0.10 to $0.20 per sq. ft. of floor area) pales compared to its benefits. Consider incorporating EBTRON into your next high‐performance building!

EBTRON, A measurable difference!

ABOUT THE AUTHOR

David Dougan has 40 years of experience with EBTRON, Inc., a leading manufacturer of airflow measurement technology. Dougan has been President of EBTRON since 1993, with prior experience as the Director of Product Development for EBTRON. Dougan has been integral in designing and developing products that set new industry standards throughout his tenure. Dougan has authored and published numerous airflow measurement and control papers featured in industry publications such as the ASHRAE Journal. His expertise in measuring and controlling airflow rates for acceptable indoor air quality and building pressurization has made him a sought-after guest speaker.