The EBTRON Duct & Plenum Probe Placement Guide and the EBTRON Placement Tool provide the essential information for successful probe placement in ducts or plenums.

Download:

Probe Placement Guide

Probe Placement Tool.

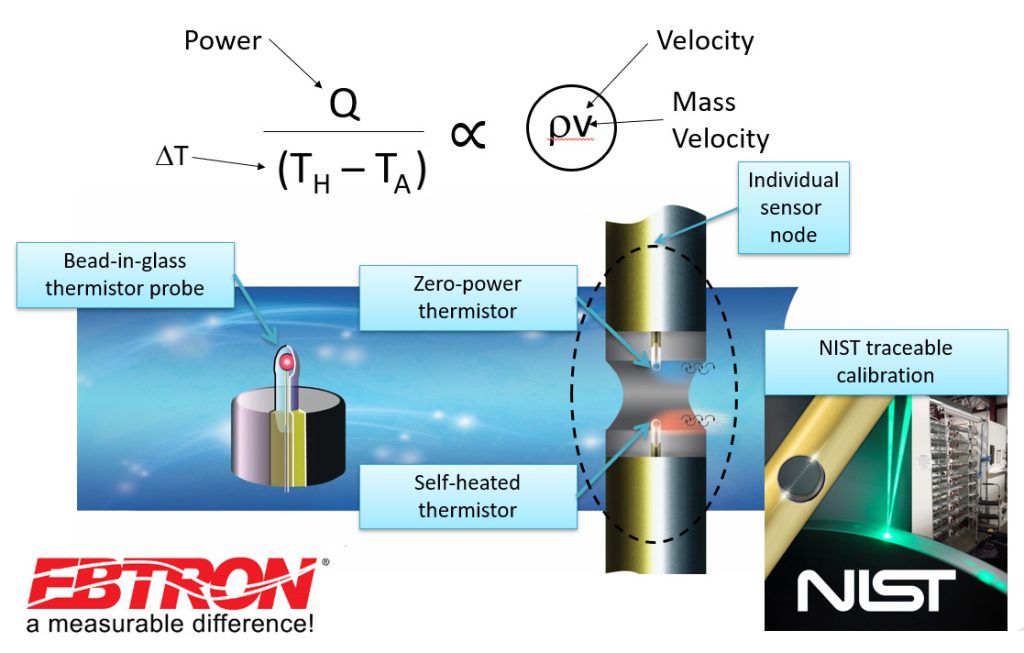

A thermal dispersion airflow measuring station is a comprehensive system that accurately measures, monitors, and validates airflow rates within ducts or HVAC systems. Thermal dispersion airflow meters are sensors that operate based on the principle of heat transfer. As the air flows past the heated sensor element, the sensor cools down and measures the flow rate of air passing through the duct. The airflow rate is accurately determined by measuring the temperature difference between the sensor and a reference element. Thermal dispersion airflow meters are known for their high accuracy, reliability, and ability to measure low flow rates. It typically consists of multiple components, including:

Probe that consists of at least one thermistor node, consisting of two thermistors, to determine the velocity and, thereby, the airflow rate of an airstream. The greater the number of nodes within the airstream, the greater the measured accuracy. Each node is an independent temperature and airflow measurement point.

The transmitter (control) unit receives the data from the airflow meters and processes it to calculate the airflow rate in the duct. It may also include features for data logging, calibration, and communication with external systems.

Optional sensors, such as relative humidity sensors, may be included in some AFMS to provide more comprehensive data on the air quality and conditions within the duct.

Integration with building management systems: Many airflow measuring stations are designed to integrate seamlessly with building automation or management systems, allowing for centralized control and monitoring of HVAC systems.

Overall, thermal dispersion airflow measuring stations play a crucial role in ensuring proper ventilation, energy efficiency, and indoor air quality in commercial and industrial buildings.

To help you as quickly as possible, we will need your first and last name, company, phone number, and email address. What are you trying to resolve? If you have an EBTRON product with a question, provide the Reference (REF) number, model, and serial number from the airflow station.

Airflow measurement ensures continuous monitoring and control of ventilation rates, essential for meeting ASHRAE standards and ensuring optimal indoor air quality, even in low-occupancy areas.

Compartmentalized pressure control, enabled by airflow measurement, prevents contaminants and ensures proper pressurization, which is crucial for maintaining indoor air quality in sensitive environments like hospitals and laboratories.

Airflow measurement allows for optimized damper/fan sequencing strategies, reducing pressure drop and resulting in up to 25% fan energy savings while improving the stability of airside economizer temperature control.

EBTRON’s quality airflow measurement devices provide years of trouble-free operation, continuously monitor, and control system performance, and validate the function of critical components like fans and dampers, contributing to sustainable building practices and long-term operational success.

© 2023, EBTRON, Inc.